Our Services

We offer a range of services, each tailored to our client’s individual requirements.

Installation Services

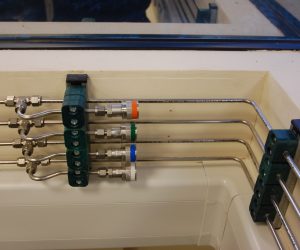

We provide high purity gas systems to clients from a wide range of different fields, from colleges, universities and science parks to the manufacturing industry providing them with systems tailored to their needs. We specialise in the installation of high pressure, high purity piped gas systems, Laboratory refurbishments (research and development, GC, GCMS, AA, Analytical, pharmaceutical, chemistry and many more), extensions to existing piped laboratory gas systems and the supply and installation of laboratory gas control equipment (from the manifolds outside to the point of use regulators). In research and development laboratories, precision is everything. So allow Specialised Gas Installations to deliver the specialist high purity pipeline systems you need, with the quality, accuracy and integrity that you want.

In every circumstance we will always give you our best advice and robust commercial terms for the pipeline installation and equipment you will require, we do not compromise on quality in order to have the lowest price, our systems are designed to give superior service and longevity of life.

All our work is carried out to the strictest of standards. This aids our clients in ensuring that all pipeline installations align with the legislation requirements under the codes of practice set out by BCGA (British Compressed Gases Association), whom we have been a full member for many years.

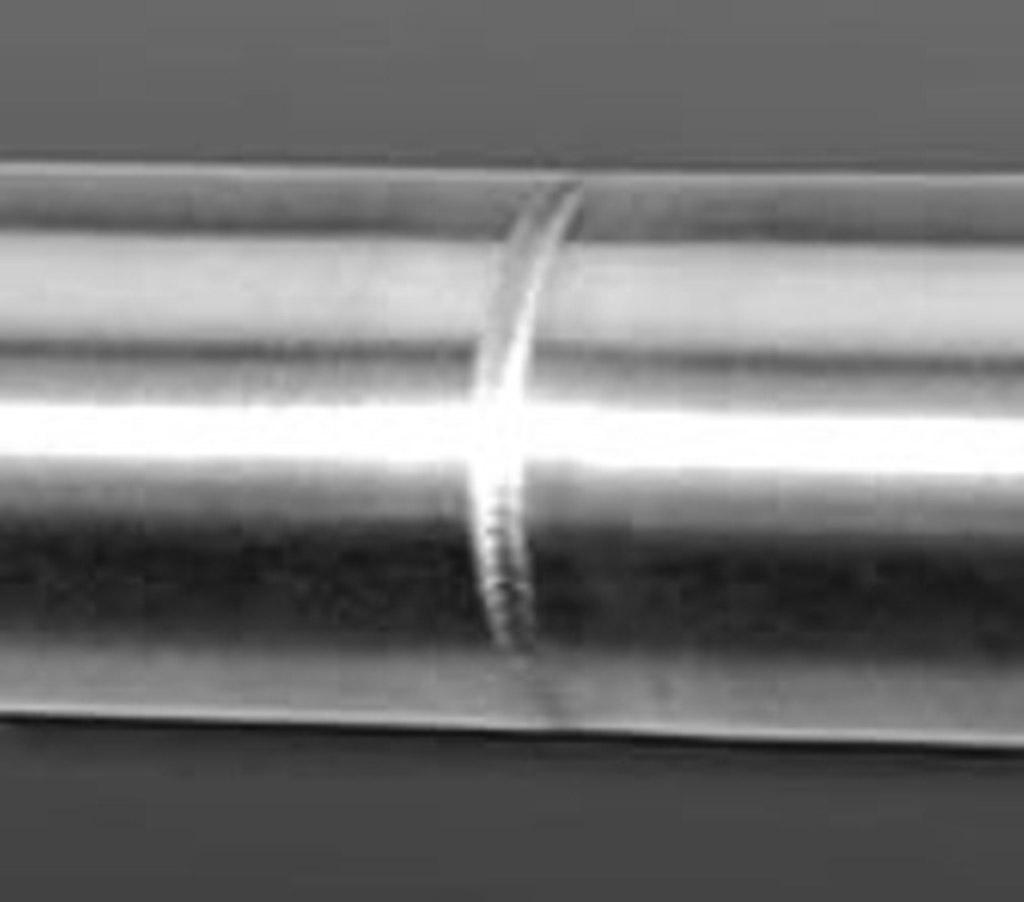

As a company, we take immense pride in all aspects of our work. The materials we use are of the highest quality, this is to ensure the required purity of each gas system is achieved. When using 316L stainless steel tube, where possible, all joints are Orbital Welded. Using our Swagelok M200 Orbital Welder, we are able to offer our clients the option of having their high purity Stainless Steel gas lines welded. Automatic orbital welding provides precision and reliability compared to manual techniques, providing the ability to make controlled, repeatable, high-quality, and well-documented welds. Having systems welded also minimises the possibility of leaks on the pipework, which in turn reduces downtime and eliminates the risk of contamination.

Our engineers have completed the Swagelok Orbital Welding Training and are very experienced using it on site through many years of operation.

Maintenance, Test and Inspection

As part of Specialised Gas Installations Limited’ continued commitment to our clients, we offer a yearly test and inspection service on all gas systems. This is to ensure your gas control equipment, including all safety devices, operate correctly and at the required pressures. This work is carried out to comply with the BCGA Codes of Practice. We will make recommendations on how to improve the system, and also draw your attention to equipment coming to the end of its service life.

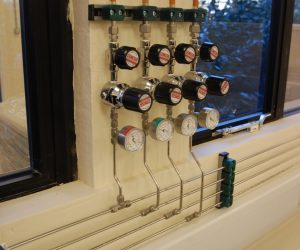

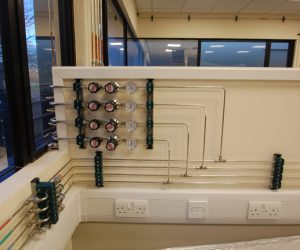

Panels

We manufacture Stainless Steel or Aluminium panels to mount your gas control equipment on. These can be used to aid the end user, either having all pipework hidden with valve handles and gauges on display (generally on more complex panels or for process machinery) or having all equipment and pipework mounted on show. Whichever one required, they prove very popular when installed and commissioned, and with an exceptionally high level of workmanship, they look fantastic too!

Gas Cages

As a company, we manufacture all our cages that we supply, fully compliant with all regulations of the BCGA CP18. They are made from Galvanised Steel so will be very strong, weatherproof and secure. They can be made to any size with different configurations dependant on your site requirements.

The cages can be used to house your gas control equipment feeding your piped systems, or as a storage for full and empty cylinders.

Orbital Welding

The materials we use are of the highest quality, this is to ensure the required purity of each gas system is achieved. When using 316L stainless steel tube, where possible, all joints are Orbital Welded. Using our Swagelok M200 Orbital Welder, we are able to offer our clients the option of having their high purity Stainless Steel gas lines welded. Automatic orbital welding provides precision and reliability compared to manual techniques, providing the ability to make controlled, repeatable, high-quality, and well-documented welds. Having systems welded also minimises the possibility of leaks on the pipework, which in turn reduces downtime and eliminates the risk of contamination.

Our engineers have completed the Swagelok Orbital Welding Training and are very experienced using it on site through many years of operation.